Fibre and particle reinforced light metals are a powerful alternative to replace classic non-reinforced metals for high demanding applications. Their high specific strength and stiffness enable new lightweight solutions. In addition, they present enhanced tribological properties and increased creep resistance at elevated operating temperatures.

The traditional manufacturing routes of MMC are based on liquid state processes in which the filaments are in contact with molten metals. For this reason, traditional reinforcements for reinforcing of metals are ceramic fibers, which are not competitive for applications in the automotive sector due to their high costs.

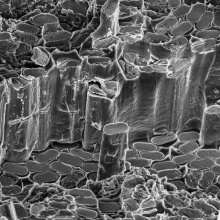

The Semi Solid Forming and Shaping (SSFS) process developed at the IMTCCC enables the production of MMC components by thermal spraying of fiber prepregs with a subsequent thixoforming process. The main benefit is a minimum fiber load due to the reduced manufacturing temperature, which remains under the liquidus line of the alloy. This low temperature process allows the use of carbon fibers as reinforcing material, which is the key for the product competitiveness and the application of MMC in series quantities.