The classic lightweight materials used in automotive and aircraft construction, such as glass and carbon fiber-reinforced plastics do not offer a sufficient thermal resistance. Metallic lightweight solutions made of aluminium or magnesium are also not capable for high temperatures due to softening effects and lead to a temperature transfer into underlying structures due to their high thermal conductivity.

Ceramic composites are a technically interesting solution. These materials consist of a ceramic matrix and ceramic fibers, enabling their use at temperatures of up to 1200 °C in air. However, their high manufacturing costs linked to high-priced fibers and complex high-temperature processes in manufacturing limit their application exclusively to aerospace applications. They are therefore not suitable for mass applications in automotive engineering, transport or technical building equipment.

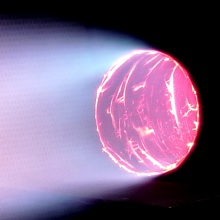

Novel semi-ceramic hybrid composites are capable for closing the gap between polymer and ceramic composites. The introduction of mineral fibres with a partially ceramic matrix enables their exposition to temperatures up to 1000 °C under fire exposure. Flexible manufacturing processes enable complex formed, thin-walled fire protection structures such as those used in the field of hot gas systems, engine compartments or battery systems. They combine the potential of lightweight construction and fire resistance with a cost-effective raw material base and manufacturing technologies suitable for mass production.