Material development, process development and verification are linked together. In addition to the complete process know-how, the characterization and verification of the materials and components at the institute are also part of the process. A main focus of the department is on cost-effective new developments in the field of high-temperature composites for the conversion into high-volume serial applications.

Further research topics

- High performance brake materials

- High temperature polymers

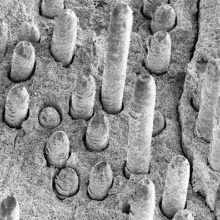

- Ceramic composites (CMC)

- 3D-reinforcement (thru-thickness) for ceramic composites

- Alternative fiber materials

- High performance friction materials

- Particle and fiber reinforced polymeric cement

- Cutting protection fabrics

- Electromagentic shielding in lightweight construction

Manufacturing Technologie

- Resin Transfer Moulding (RTM, VaRTM)

- Vacuum Infusion (VARI)

- Warm pressing

- SMC

- Ceramic Pultrusion

- Polymer Infiltration and Pyrolysis (PIP)

- Liquid Phase Siliconizing

- Filament-Wet-Winding

- Fiber preforming / Handling

Materials

- Fiber and particle reinforced light metals (MMC)

- Fiber reinforced Ceramic Matrix Composites (CMC)

- High temperature Polymer Matrix Composites up to 400 °C (PMC)

- Polymer based fiber reinforced ceramics and hybrid composites for elevated temperatures up to 1000 °C

- Lightweight materials for tribological systems (e.g. high performance brake rotors)

- Fire protection / nonflammable composites

- Lightweight heat shielding and insulation materials

- Ballistic protection