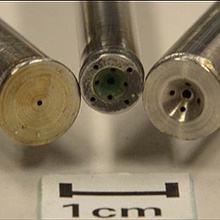

High Velocity Suspension Flame Spraying (HVSFS) puts high demands on the injection of the suspension, since it is injected directly into the combustion chamber. Through redesign of the suspension injectors, process stability can be increased and handling can be simplified. A controlled atomisation is also possible. In this context, the interaction with respective suspension properties and different feeding principles has to be considered. The liquid break up and atomization effects of an added atomization gas as well as the effect of different break up modes on coating properties are experimentally investigated.