Additive manufacturing processes, commonly referred to as 3D printing, are a promising family of manufacturing technologies. Thanks to 3D printing, plastics, metals and also ceramic materials can be processed layer by layer and in small numbers economically and resource-efficiently to form complex components. Especially in the context of digitalization and Industry 4.0 additive manufacturing is a key technology for the production facilities of the future. 3D printing also enables the production of patient-specific implants, for example for bone, tooth or joint replacement.

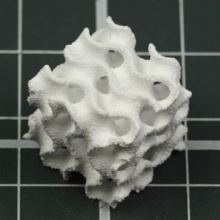

At Institute for Manufacturing Technologies of Ceramic Components and Composites, research into additive manufacturing of ceramics with a focus on medical applications is being pursued. The focus is on the development of highly porous bone replacement structures, so-called "scaffolds" based on calcium phosphates and bioactive glasses. The validation of the biocompatibility of the printed structures is carried out in close partnership with the Medical Center – University of Freiburg.

The technologies for manufacturing the geometrically complex, porous bioceramic structures are

- Inkjet 3D printing

- Selective Laser Sintering

- Ceramic-based Stereolithography

- Fused Deposition Modelling